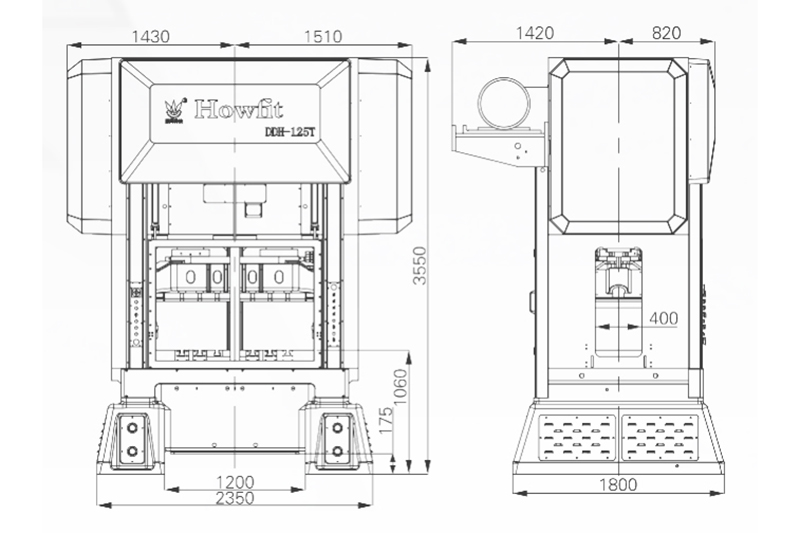

I-DDH-125T HOWFIT High Speed Precision Press

Amapharamitha Obuchwepheshe Ayinhloko:

| Imodeli | I-DDH-125T | |

| Umthamo | KN | 1250 |

| Ubude be-stroke | MM | 30 |

| I-SPM ephezulu | I-SPM | 700 |

| I-SPM encane | I-SPM | 150 |

| Ukuphakama kwedayi | MM | 360-410 |

| Ukulungiswa kokuphakama kwedayi | MM | 50 |

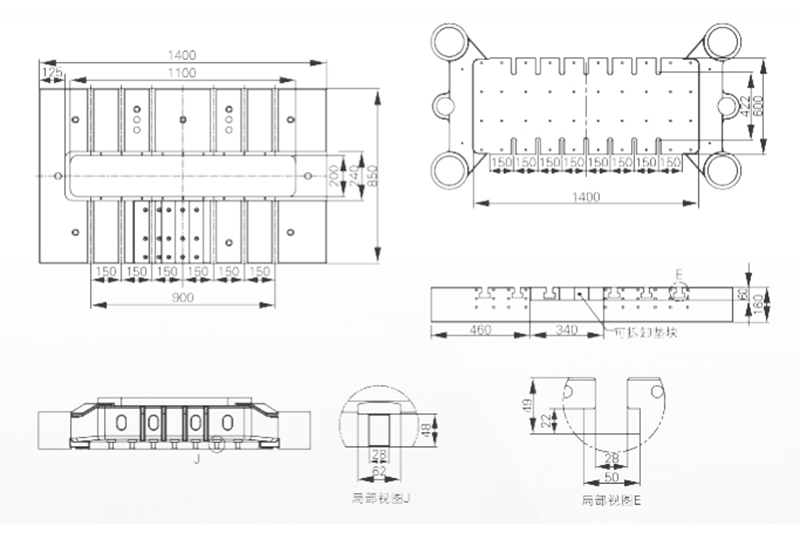

| Indawo yesilayida | MM | 1400x600 |

| Indawo ye-Bolster | MM | 1400x850 |

| Ukuvula umbhede | MM | 1100x300 |

| Ukuvulwa kwe-Boost | MM | 1100x200 |

| Injini eyinhloko | KW | 37x4P |

| Ukunemba |

| OkumangalisayoIbanga elikhethekile le-JIS/JIS |

| Isisindo Esiphelele | I-TON | 27 |

Izici Eziyinhloko:

♦Uhlaka lwenziwe ngensimbi eqinile kakhulu, eqeda ukucindezeleka kwangaphakathi kwento yokusebenza ngokusebenzisa isikhathi eside semvelo ngemuva kokulawulwa kwezinga lokushisa okunembile kanye nokushisa, ukuze ukusebenza kwento yokusebenza yento yohlaka kufinyelele esimweni esihle kakhulu.

♦Ukuxhumeka kohlaka lombhede kuqiniswa yi-Tie Rod futhi amandla e-hydraulic asetshenziselwa ukucindezela isakhiwo sohlaka kusengaphambili nokuthuthukisa kakhulu ukuqina kohlaka.

♦I-clutch kanye ne-brake yokuhlukanisa enamandla futhi ebucayi iqinisekisa indawo eqondile kanye nokubhuleka okubucayi.

♦Idizayini enhle kakhulu yebhalansi eguquguqukayo, inciphisa ukudlidliza nomsindo, futhi iqinisekisa impilo yedayi.

♦I-Crankshaft isebenzisa insimbi ye-alloy ye-NiCrMO, ngemva kokwelashwa ngokushisa, ukugaya kanye nokunye ukucutshungulwa okunembile.

♦I-axial bearing engacaci isetshenziswa phakathi kwesilinda somhlahlandlela wesilayidi kanye nenduku yomhlahlandlela futhi ifaniswe nesilinda somhlahlandlela esinwetshiwe, ukuze ukunemba okuguquguqukayo nokungaguquki kudlule ukunemba okukhethekile okukhulu, futhi impilo yedayi yokunyathela ithuthuke kakhulu.

♦Sebenzisa uhlelo lokupholisa oluphoqelelwe lokugcoba, wehlise ukucindezeleka kokushisa kohlaka, uqinisekise ikhwalithi yokunyathela, wandise impilo yokucindezela.

♦Isixhumi esibonakalayo somshini womuntu silawulwa yi-microcomputer ukuze kufezwe ukuphathwa okubonakalayo kokusebenza, inani lomkhiqizo kanye nesimo samathuluzi omshini ngokusobala (uhlelo lokucubungula idatha oluphakathi luzosetshenziswa esikhathini esizayo, futhi isikrini esisodwa sizobona isimo sokusebenza, ikhwalithi, inani kanye nolunye ulwazi lwawo wonke amathuluzi omshini).

Ubukhulu:

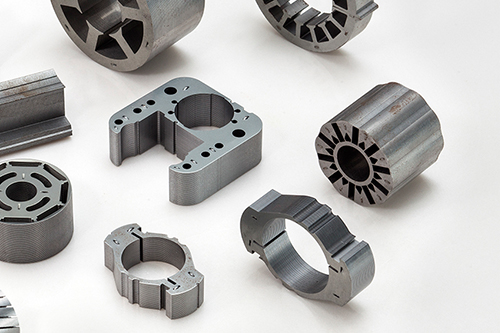

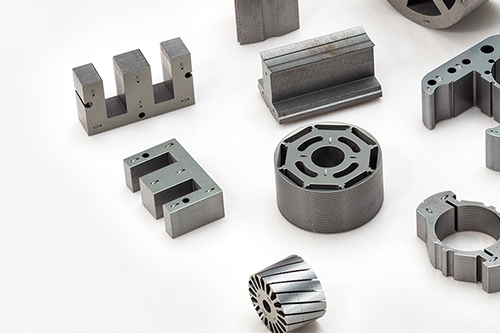

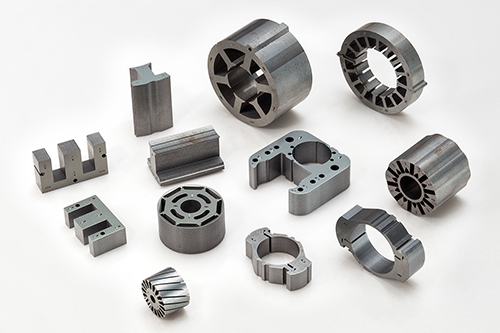

Imikhiqizo Yabezindaba: